Commercial lighting is a growing market worth over $8.2 billion. Large commercial buildings, warehouses, industrial plants and their high ceilings require a specialized lighting setup to provide enough illumination. This sparks the following common question: What’s the Difference between High Bay & Low Bay Light Fixtures?

Upgrading to LED lights are now the preferred alternative to fluorescent lamps, but they come in several varieties. Two of the most useful for large spaces with fairly high ceilings are high and low bay lighting fixtures.

The two types have several similarities, such as the fact that they’re both mounted onto high ceilings. The important thing to remember before purchasing them is that they also have several differences that make them specialized for unique situations.

Read our high bay vs. low bay lighting comparison guide to learn what these fixtures do and how to choose between them.

What is Bay Lighting?

A bay light illuminates a large area with a high ceiling. Application examples include warehouses, commercial buildings, retail locations, and gymnasiums.

There are two main categories; high and low bay light fixtures. The primary characteristic used to tell them apart is ceiling height, but they have other similarities and differences.

High Bay vs Low Bay Lighting

High and low bay lighting fixtures are both used to illuminate large areas and mounted onto high ceilings to provide stronger light while reducing glare.

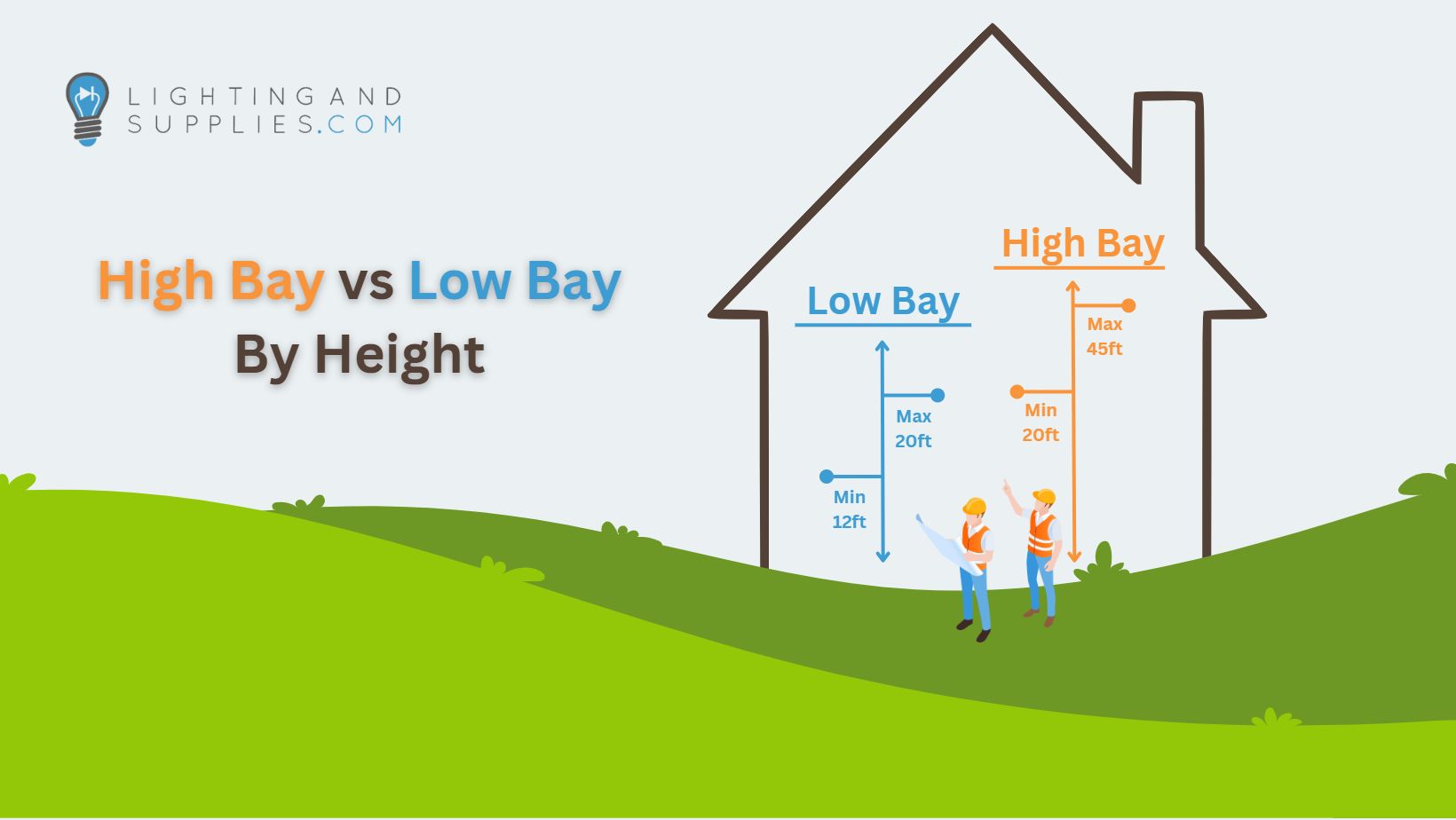

Ceiling height is the best way to compare high bay vs. low bay lighting. Low bay fixtures only work with ceilings that are between 12-20 feet high. High bay light fixtures can illuminate ceilings that are 20-45 feet high.

The lightings also differ in strength. Low bay lighting is below 100 watts while high bay lighting can go above 100 watts.

The lighting fixtures use different hanging methods. Low bay lighting is suspension mounted with chains or hooks. High bay lighting can hang from the ceiling using a hook, chain, or pendant or fixed to the ceiling directly like a troffer light.

Manufacturing Industrial Bay Lights

The manufacturing process is also different for each type. A low bay lighting fixture includes reflectors or lenses to spread light and reduce glare. A high bay light fixture needs special reflectors made of either aluminum to make the light flow down to the floor or prismatic components to diffuse the light and illuminate shelves and other elevated objects.

There are more varieties of high bay lights. They can be used in LED, induction, metal halide, or fluorescent light fixtures. Types include round, linear, architectural, and grid-mount.

High bay light fixtures have a larger range of applications, including industrial and manufacturing facilities, warehouses, gymnasiums, community or recreation centers, airport hangars, and department stores or other commercial building lighting applications.

Differences between High Bay and Low Bay Lights

In short, High bay lights are designed for use in spaces with ceilings that are 15 feet or higher, whereas Low bay lights, on the other hand, are designed for use in spaces with ceilings that are less than 15 feet, such as retail stores, offices, and schools. They typically have a lower lumen output and a narrower beam angle than high bay lights.

In summary, high bay lights are meant for higher ceilings and provide more light, while low bay lights are meant for lower ceilings and provide less light.

Below is a breakdown comparing the two types of fixtures in more detail.

1. HEIGHT OF INSTALLATION:

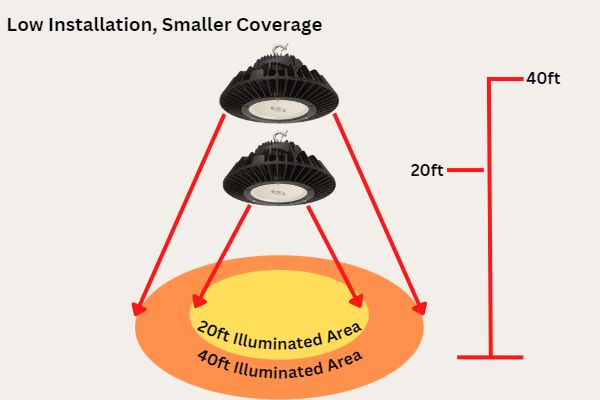

High bay lights are used to light up spaces whose ceilings are higher than 20ft from the floor and around 40ft.

Also, for these lights to operate efficiently from this height, they need specially engineered reflectors in the case of HPS / MH bulbs and lens angles in the case of LED high bays.

What this does is to ensure that the light gets to the floor evenly, and it is not wasted.

On the other hand, low bay lights are intended for use in ceilings whose height is below 20ft from the ground.

Specifically, the ceiling can be between 12 ft to 20 ft.

As such, these lights are mostly used in homes, public buildings, and retail businesses.

2. APPLICATION:

High bay lights are used in industrial and commercial spaces, and an instance is the high bay warehouse lighting.

Some areas of application of high bay lights include:

- Storage Facilities

- Factories

- Warehouses

- Airport hangars

- Government & Municipal facilities

- School and university gymnasiums

Nonetheless, low bay lights can still be employed some of these locations, but it’s still worth pointing out that some areas of its application include:

- Warehouse

- Frozen Storage

- Gas Station

- Retail Stores

- Restaurants

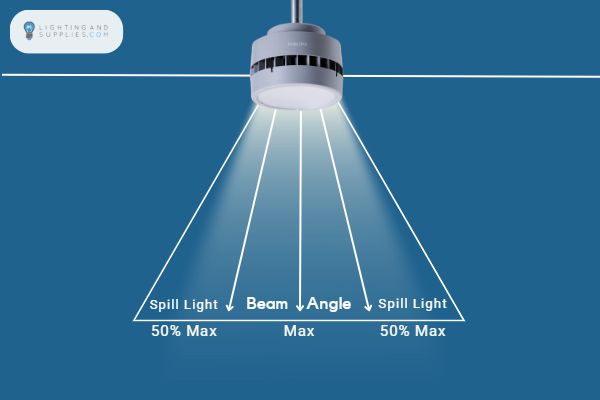

3. BEAM ANGLE:

High bay lighting uses common beam angles such as 60°, 90°, and 120°.

A narrow beam helps to create a more focused beam that provides a high lux level on the floor.

In contrast, a wider beam angle allows large open areas with lower roof height to have an excellent distribution of light.

That aside, low bay lights have a beam angle of 120°.

With low bay lights, lens angles are employed to spread the light further to maintain the desired lighting level, and this lens angle helps to direct the light in specific places.

4. MOUNTING:

High bay lighting fixtures can be hung from chains or pendants, ceilings using hooks, or they can be fixed directly to the ceiling.

A range of fixtures can be used for high bay lights, and some of these include grid-mount high-bays, linear high-bays, round high-bays, UFO high0-bay lights and architectural high-bays. Choosing the correct high bay light bulbs are also part of this process.

Consideration for the use of high bay lights is it can light vertical surfaces and also light the floor.

There are warehouses where vertical lighting is important since it could help in picking items from the shelf.

Major Differences Between High Bay and Low Bay Lights

Despite the disparity between high bay vs. low bay lights, their most peculiar difference lies in the ceiling height for their installation.

For height below 20ft, low bay lights are suitable, whereas high bay lights can be used in spaces whose ceiling is over 40 ft from the ground.

There is a technical difference between either, which lies in their lumen output and direction of light.

Lower lights will need less lumen output because they tend to lose less light.

In this case, low bay lights use fewer lumens compared to high bay lighting, and as such, they don’t have to perform as hard.

The high lumen output of a high bay light can be attributed to the greater distance they are installed, and as such, it needs to be compensated for, to reach vital areas, and to prevent shadows.

On the same note, the reflector or lens angles may differ since different heights need different direction and light placement.

High bay lights, for instance, will take advantage of reflectors that ensure that the light spreads down and out to provide visibility in the space despite the distance it is installed.

How to Choose the Right Bay Lighting

High bay and low bay indoor light fixtures are quite popular in commercial and industrial places.

A choice between either depends on the region they will be mounted and the level of brightness that is required.

Also, choosing one over the other can significantly impact the safety of your facility as well as the efficiency of operations in your workplace.

That being so, there are several differences between high bay and low bay lighting, which sets either apart and gives it an advantage over the other.

Knowing the differences between high bay vs. low bay lighting helps you choose the right type for your building. There are other factors to keep in mind as well, such as bulbs, power, and energy usage.

Below, we outline what we think are the 9 most important variables to consider when you’re looking to install high or low bay light fixtures.

1.) LED VS. FLUORESCENT BULBS

The first choice you should make when deciding on what type of lighting design setup to use is what type of light bulbs you need. LED sales exceeded 10 billion units in 2019. They’ve officially overtaken fluorescent lamps as the most popular option.

This growth is thanks to a range of benefits. Switching to LED lighting lasts 25 times longer, uses 75% less energy, and is easier to install than traditional fluorescent lamps. It also allows you to take advantage of special utility lighting rebates and enjoy lower energy and disposal costs.

2.) HIGH BAY VS. LOW BAY LED LIGHTING

High Bay and Low Bay are lighting terms used to describe the correct bay lights needed for the appropriate ceiling height.

When you need to illuminate a large space, you must decide between high bay LED lighting or low bay LED lighting. The first step is to measure the height of your ceiling and consider what type of space you want to illuminate.

3.) BEAM ANGLE AND WIDTH

You should look for a beam angle that matches the light fixture’s height. Options for high bay lighting fixtures include 60°, 90°, or 120°.

Once you know the beam angle, you can calculate the beam width. Use the formula beam angle x 0.0.18 x distance from the light bulb.

4.) MOUNTING AND DISTRIBUTING OPTIONS

There are several mounting options to choose from, including slip filters, trunnions, and straight arms. Find the right one for your needs before creating your lighting setup.

There are two different types of light distribution patterns to choose from. Type III is best for parking lots and roadway lighting because it’s taller but not as widespread. Type V is shorter but spreads the light over a larger area.

5.) RETROFITTING

Retrofitting kits come with most LED lighting fixtures. They include slip fitter brackets, trunnions, an arm, and other essential components.

Using these kits helps you save money and time. Consider them if your current lights are in acceptable condition and just need to be fitted with LED bulbs.

6.) POWER

If your lighting fixture isn’t powerful enough, it won’t be able to illuminate the entire space. Try to find light fixtures with at least 130 lumens per watt.

7.) COLOR TEMPERATURE

Find the right color temperature. Warmer colors are more comforting, but blue provides the most visibility.

8.) SHAPE

Keep the lighting fixture’s shape in mind. Round lights illuminate almost any large space, but rectangular lights are better for long workbenches and production lines.

9.) ENERGY USAGE

LED lights reduce your energy usage, but additional components increase this effect. Consider adding dusk to dawn photocells, motion sensors, and dimmers. They’ll ensure your lights only work at full power when you or your staff and customers are around.

Where to Buy Bay Lights

Every product you consider should have a DLC qualification, a form of quality assurance for LED lighting.

When you’ve considered all of the necessary factors, find the right provider to get your lighting fixtures from. They should be willing to show you all their quality products and guide you to the right choice.

If you need help finding a Sales Rep or Commercial Light Fixture Distributor in the United States, contact us today at 888-325-4448 or email us at [email protected]

Where to Get the Best Lighting Fixtures

Warehouses, retail locations, and other commercial buildings require their own unique lighting setups. Bay lighting is a popular option.

Measuring the ceiling height is one of the best ways to decide between high bay vs. low bay lighting fixtures. They each have their own advantages, and one may suit your needs better than the other.

Add LED bulbs to your high or low bay lighting. Consider other factors including beam angle and width, power, color temperature, shape, and energy usage.

At Lighting and Supplies, we have a range of options to illuminate any type of building. Browse our lighting fixture solutions today.

Top Rated Wholesale LED Lighting Supplier – Lighting and Supplies

As one of the best wholesale lighting distributors in the United States, Lighting and Supplies provides a wide variety of indoor and outdoor light fixtures to accommodate all of your customers’ commercial and residential electrical and lighting project needs. For electricians, contractors, lighting engineers, project managers and more, we can help source the lights you need by providing a lighting quote or creating a proposal for the right lights in your lighting specification process or next lighting design project.

Click here for more information about Lighting and Supplies.

Need help? Contact us today at 888-325-4448 or email us at [email protected]!